Dirty Connections Can Result In Dirty Data

Tags: cleaning | Fiber optics | inspection

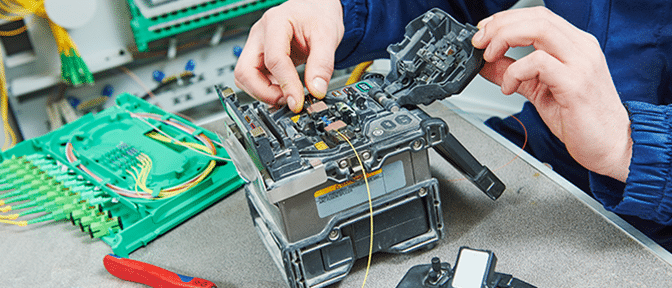

Cleaning and Inspection of Optical Fiber Connectors

Cleanliness of fiber optic connections is critical to the performance of optical communication networks. Contamination – dirty fiber – on a connector end face, even if only at the microscopic level, can create severe problems.

Traditional single-mode fiber optic core diameters are approximately 9 microns. By comparison, a human hair is 50 microns or larger in diameter. Dirt on the fiber end face that blocks the fiber core generates strong back reflections (Return Loss), and may impact attenuation (Insertion Loss).

Loose contamination on the connector end face may move during mating, or may prevent physical glass-to-glass contact required for proper signal transmission. Rigid contamination trapped between connector end faces may permanently damage the fiber core(s).

Dry contamination or dirt is relatively simple to remove compared to oils and films which naturally occur with human contact, vapor condensation, and solvent evaporation.

Cleaning Single Fiber Connectors and Adapters

Dry Cleaning:

Using a reel-based cassette cleaner with medium pressure, wipe connector endface against dry cleaning cloth (single swipe per exposure) in one direction. For angled physical contact (APC) polished connectors, ensure that entire endface surface mates with the cleaning cloth. Dry cleaning will generally remove airborne contamination and should be attempted first. Inspect connector endface for contamination after cleaning.

Another method is to use single fiber In-bulkhead cleaners that are specially designed for both physical contact (PC) and angled physical contact (APC) polished connectors. These devices feed a cleaning cloth across a head while the head rotates. Cleaning cloth is advanced to ensure it is clean. Always inspect connector endface for contamination after cleaning.

Wet Cleaning:

Lightly moisten portion of a lint free wipe with fiber optic cleaning solution (or > 91% Isopropyl Alcohol) and by applying medium pressure, first wipe endface against wet area and then onto dry area to clean potential residue from the endface.

For APC polished connectors, ensure entire endface surface mates with the cleaning wipes. Wet cleaning is more aggressive than dry cleaning, and will remove airborne contamination as well as light oil residue and films. Perform dry cleaning as described above after wet cleaning and inspect connector endface for contamination after cleaning.

Caution: Always clean sides and tip of ferrule. Core alignment may be affected if ferrule is not thoroughly cleaned.

Bulkhead Adapter Cleaning

Dry Cleaning:

Insert appropriate size cleaning stick tip into the adapter until a contact is made with the connector on the opposite end. Cleaning sticks are available for both 1.25 mm ferrule connectors (LCs) and 2.5 mm ferrule connectors (SC and ST).

Rotate the cleaning stick with medium pressure in one circular motion as it is pulled from the adapter. Inspect endface for any contamination after cleaning.

Wet Cleaning:

Insert a lightly moistened appropriate size cleaning stick tip with fiber optic cleaning solution (or > 91% Isopropyl alcohol) into the adapter until a contact is made with the connector on opposite end. Rotate the cleaning stick with medium pressure in one circular motion as it is pulled from the adapter.

Follow up with a dry cleaning stick and complete with dry cleaning method using In-bulkhead- cleaners. Always inspect connector endface for contamination after cleaning.

Caution: Discard cleaning sticks after each use. Do not turn the cleaning stick back and forth pressing against connector endface, this may cause scratches if a large contamination is present.

Cleaning Multi-Fiber Array Connectors (MPO) And Adapters

There are special cleaners available, which can be used for the pinned and the unpinned (PC and APC polished) MPO connectors. For APC MPO connectors, ensure that entire endface surface mates with the cleaning cloth. Another method is to use reel based MPO In-bulkhead cleaner specially designed for cleaning both the pinned and the unpinned (PC and APC polished) MPO connectors.

Caution: To prevent scratching the end face, always clean the MPO connectors with a cleaning motion from top to bottom perpendicular to fiber array. Never clean the MPO connector by rubbing across it from side to side (parallel to fiber array).

Warning

As compressed air products have the potential to deposit moisture and propellant debris on critical optical surface, it is not recommended the use of any canned air product when cleaning a fiber optic connector surface.

Check out the Network Test, Inspection and Troubleshooting courses for more information.

Written by James Donovan

You might also enjoy

FO Connector Contamination – A Constant Threat

Fiber optic communication most commonly works in duplex or multifiber transmission by transmitting light to a receiver in one direction on a fiber and receiving transmitted light back to a second receiver on the second fiber. Most engineers can understand that and...

Why Inspect and Clean Fiber Optic Connectors?

Inspecting and cleaning of fiber optic connectors during installation and when making any patching, is essential. Any contamination on a patch cord connector will be transferred through the coupler to the connector it is mated to. Even when testing fibers with a test...

Cleaning MPOs

MPO connectors should always be inspected with a scope before they are used, be that on a patch cord or a bulkhead. If they need to be cleaned, one-click cleaners are keyed to ensure the tip only fits one way onto the connectors and is able to clean both male and...